A hydro cone crusher refers to a specific type of cone crusher that utilizes the hydraulic system to adjust and control various crusher settings. Hydro cone crushers are a variant of gyratory cone crushers and are known for their ability to deliver a precise product size, especially in the secondary or tertiary crushing stages. Let’s explore the key features and advantages of hydro cone crushers:

Key Features:

- Hydraulic Adjustment System:

- One of the defining features of hydro cone crushers is the hydraulic adjustment system. This system allows for quick and easy adjustments of the crusher settings, including the closed-side setting (CSS), ensuring precise control over the product size.

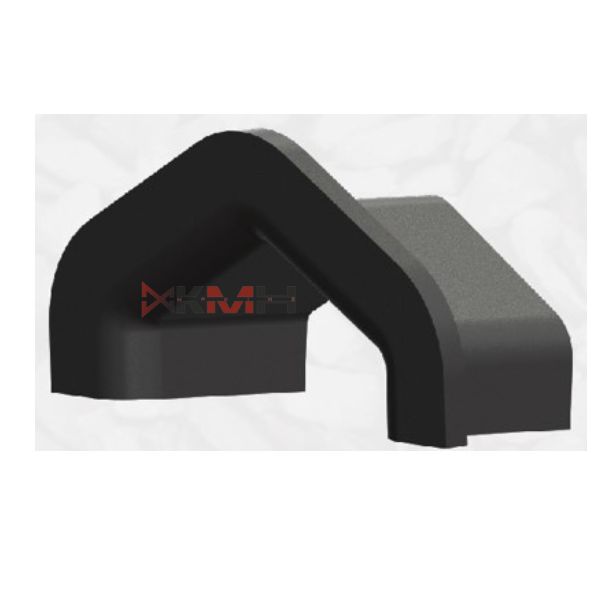

- Crushing Chamber Design:

- Hydro cone crushers typically have a crushing chamber with a concave or bowl liner and a mantle. The design of the chamber promotes uniform crushing, resulting in a well-shaped product.

- Efficient Crushing Action:

- The hydraulic system provides consistent and efficient crushing action by adjusting the crusher settings based on the material being processed. This leads to improved overall performance and better particle size distribution.

- Automation and Safety Features:

- Many hydro cone crushers come equipped with advanced automation features, such as automated setting regulation (ASRi) and other safety features. These features enhance operational efficiency and help protect the crusher from potential damage.

- Versatility:

- Hydro cone crushers are versatile and suitable for a wide range of applications. They are commonly used in the mining and aggregate industries for secondary and tertiary crushing of various materials.

Advantages:

- Precision in Product Size:

- The hydraulic adjustment system allows for precise control over the product size, producing well-graded and uniform end products.

- Quick and Easy Maintenance:

- Hydro cone crushers are designed with accessibility in mind, making maintenance tasks, such as liner changes or inspections, more straightforward and efficient.

- Consistent Performance:

- The hydraulic system ensures consistent and optimized performance by automatically adjusting the crusher settings to adapt to changing feed conditions.

- Reduced Downtime:

- The ability to adjust settings hydraulically contributes to reduced downtime, as operators can quickly adapt the crusher to different feed materials without requiring extensive manual adjustments.

- Automation for Operational Efficiency:

- Automation features contribute to operational efficiency, allowing for remote monitoring, adjustment, and optimization of the crusher’s performance.

Applications:

Hydro cone crushers find applications in various industries, including:

- Mining and mineral processing

- Aggregates production

- Construction and demolition recycling

- Quarrying

In summary, hydro cone crushers offer precise control over crusher settings through hydraulic adjustment systems, resulting in consistent and efficient crushing performance. Their versatility and automation features make them suitable for a range of applications, providing reliable and high-quality end products.

KMH Makine stands out as a preferred choice for various reasons:

- Quality Products: KMH Makine is renowned for producing high-quality industrial equipment, ensuring durability and adherence to industry standards.

- Diverse Range: The company offers a comprehensive range of machinery suitable for diverse industrial applications, catering to sectors like mining, construction, and materials processing.

- Technical Expertise: With a focus on technical expertise, KMH Makine provides tailored solutions for specific industrial requirements, supported by efficient technical assistance.

- Customer Focus: KMH Makine prioritizes customer satisfaction, delivering products with excellent quality, reliable performance, and efficient service.

- Global Reputation: The company has built a strong reputation in various countries, including Turkey, Russia, Uzbekistan, Azerbaijan, Poland, Hungary, and beyond.

Choosing KMH Makine ensures access to reliable, high-performance industrial equipment, backed by a commitment to customer satisfaction and a global track record of excellence.

No comment