The choice between a cone crusher and a jaw crusher depends on the nature of the material you need to crush and the desired shape of the end result. Both types of crushers have their advantages and disadvantages. Here’s a comparison to help you understand which might be better suited for your specific needs:

Cone Crusher:

- Advantages:

- Versatility: Cone crushers are suitable for secondary, tertiary, and quaternary crushing stages. They can handle a wide range of materials, making them versatile in various applications.

- Uniform Product Size: Cone crushers produce a more cubical-shaped product compared to jaw crushers, which can be important for certain applications.

- Disadvantages:

- Higher Operational Costs: Cone crushers generally have higher operational costs than jaw crushers due to the need for regular maintenance and the cost of wear parts.

- Limited Feed Size: The feed size is limited, and excessive fines can be produced with certain types of materials.

Jaw Crusher:

- Advantages:

- Lower Initial Cost: Jaw crushers are generally less expensive than cone crushers upfront.

- Higher Capacity: Jaw crushers have a higher capacity for throughput compared to some cone crushers, making them suitable for large production plants.

- Disadvantages:

- Limited Material Size: Jaw crushers may not be suitable for materials with higher moisture or those that are sticky.

- Less Cubical Product: Jaw crushers tend to produce more elongated and flatter products compared to cone crushers.

Conclusion:

- Choose a Cone Crusher When:

- You need finer product output.

- Versatility is essential for different applications.

- Your material is hard and abrasive.

- Choose a Jaw Crusher When:

- Initial cost is a significant factor.

- You need higher capacity for large-scale production.

- Your material is not excessively abrasive.

Ultimately, the best choice depends on your specific requirements, the characteristics of your material, and your operational priorities. It’s often beneficial to consult with experts to determine the most suitable crushing solution for your application.

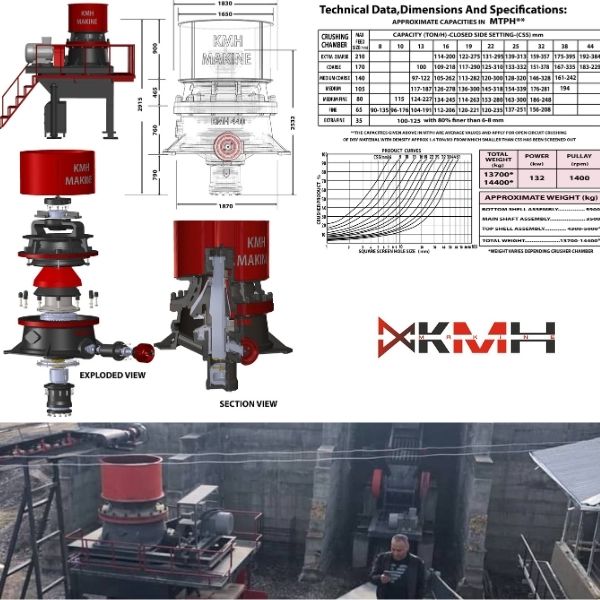

kmh makine

Absolutely! Seeking a consultation with experts at KMH Makine before making a crusher purchase is a wise and beneficial step. Their team can provide valuable insights based on your specific requirements, material characteristics, and operational needs. Here are a few reasons why consulting with KMH Makine experts is a good idea:

- Specialized Knowledge: KMH Makine specializes in manufacturing crushers and related equipment. Their experts possess in-depth knowledge about the performance, features, and applications of their products.

- Customized Solutions: Every industrial operation is unique. KMH Makine experts can assess your specific needs and recommend a crusher model that aligns with your production goals and material requirements.

- Optimal Performance: By consulting with experts, you can ensure that the selected crusher is optimized for your intended use. This can contribute to enhanced performance, efficiency, and overall productivity.

- Cost-Effective Choices: KMH Makine experts can guide you in selecting a crusher that not only meets your operational needs but also fits your budget. This ensures a cost-effective solution tailored to your requirements.

- Technical Support: KMH Makine is known for providing strong technical support. By consulting with their experts, you can gain insights into maintenance practices, troubleshooting, and overall equipment care.

To initiate this process, consider reaching out to KMH Makine through their contact channels, scheduling a consultation, and discussing your specific requirements. This personalized approach can lead to a more informed decision, helping you choose the best crusher for your industrial application.

No comment