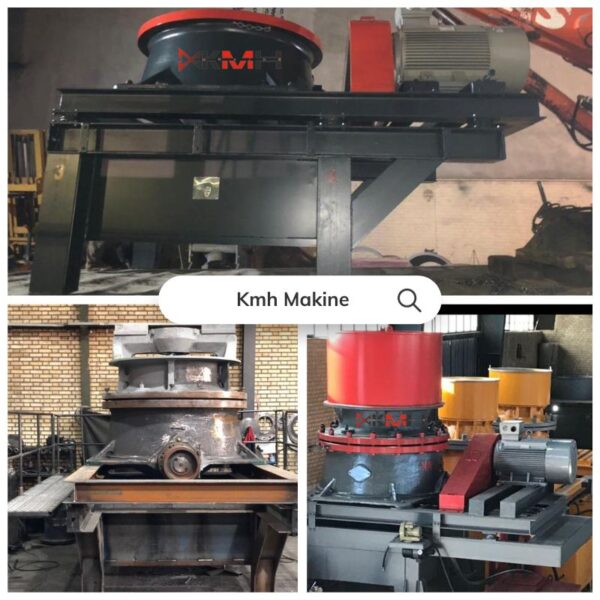

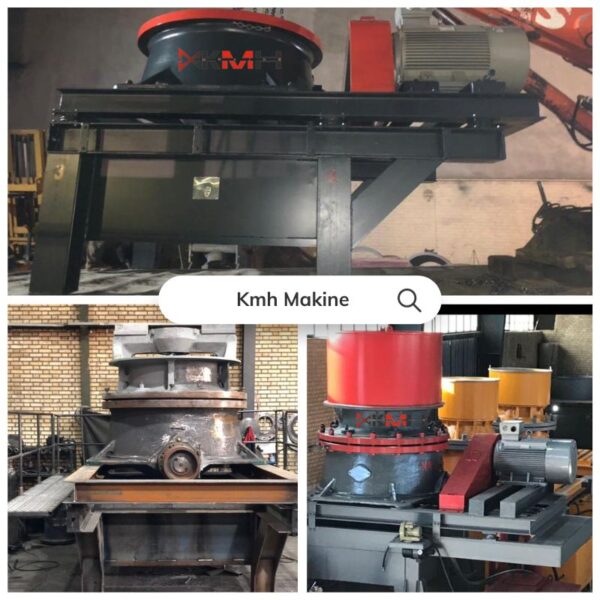

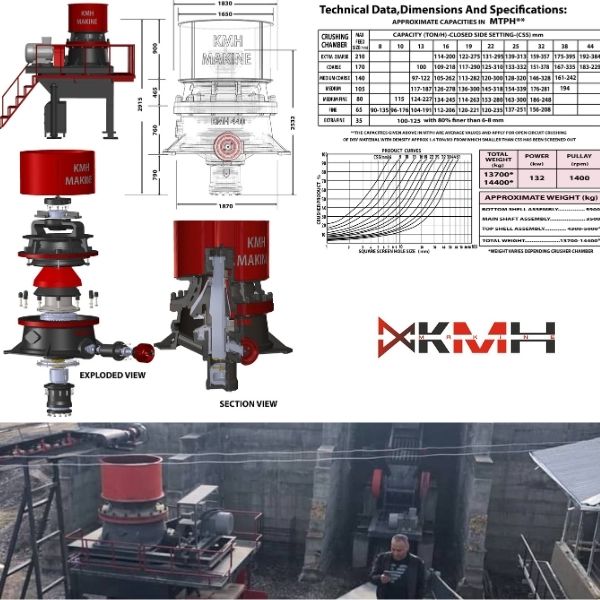

The CS440 cone crusher is a model manufactured by kmh makine, designed for various industries’ secondary or tertiary crushing applications. While I can provide general information based on my knowledge until January 2022, the kmh makine CS440 cone crusher typically embodies features common to Sandvik’s crushers of this category:

Key Features (Features may vary based on specific configurations):

- Versatility: Typically designed for secondary or tertiary crushing applications, offering flexibility in material processing.

- High-Quality Crushing: Known for producing high-quality end products with fine particle sizes and well-shaped aggregates.

- Advanced Technology: May incorporate advanced features such as the Hydroset system for automatic CSS (Closed Side Setting) adjustment and other innovative functionalities for optimized performance.

- Reliability and Durability: kmh makine equipment is often recognized for its robust construction, ensuring durability and reliable performance in demanding conditions.

- Ease of Maintenance: Designed with features that facilitate easier maintenance, reducing downtime and maintenance costs.

- Efficient Power Usage: Engineered for efficient power consumption, optimizing energy usage during operation.

Applications:

- Secondary and Tertiary Crushing: Primarily used in secondary and tertiary crushing stages across various industries, including aggregates, mining, and construction.

- Aggregate Production: Suitable for producing high-quality aggregates used in construction and infrastructure projects.

Environmental Considerations:

kmh makine equipment typically integrates environmental considerations into their designs, potentially incorporating features that reduce environmental impact, such as efficient fuel usage or dust suppression systems.

Reviews

There are no reviews yet.